Target Materials

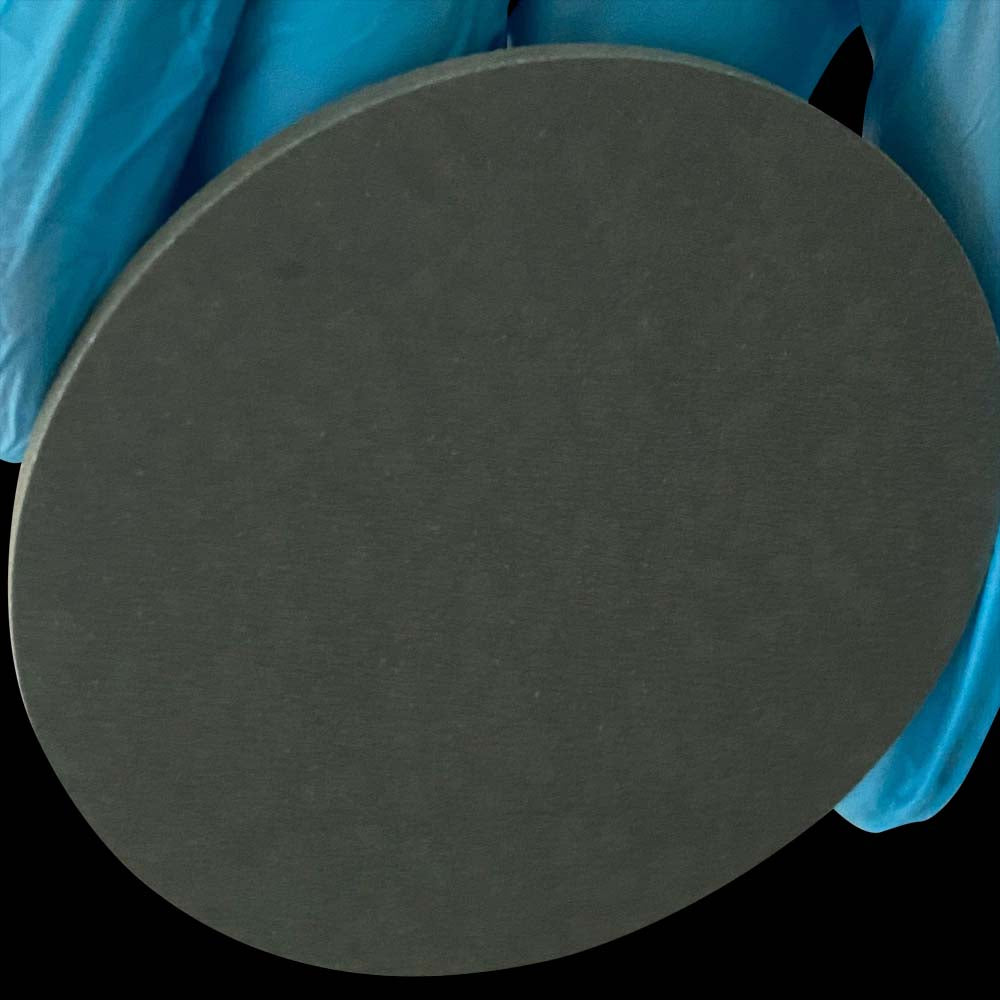

Al-doped ZnO (AZO) Sputtering Target

Al-doped ZnO (AZO) Sputtering Target

Couldn't load pickup availability

| Material | Aluminium doped Zinc Oxide |

| Formula | 2wt% Al2O3 in ZnO |

| Purity | 99.99% |

| Typical Substrates | Glass, Quartz, Polymers, Silicon and Silicon Dioxide |

| Related Materials | ITO, IGZO, ZnSnO3, ZnSnO4, ZnSnO2, TiO2, |

Aluminium-doped zinc oxide (Al:ZnO) is a transparent conducting oxide (TCO) used in many optical and electronic applications. It is formed by doping zinc oxide (ZnO) with aluminium (Al) atoms.

Al:ZnO sputtering targets are used in physical vapor deposition (PVD) processes such as sputtering and pulsed laser deposition (PLD). Al:ZnO sputtering targets are used in a variety of applications, including transparent conducting oxide (TCO) thin films for display technology, solar cells, and touch screens. They are also used in the fabrication of transparent electrodes, antireflective coatings, and gas sensors. Al:ZnO sputtering targets are also used in the production of transparent conductive oxides (TCOs) for optoelectronic applications, such as light emitting diodes (LEDs).

Typical Aluminium Concentration in Al:ZnO

The aluminium concentration in Al:ZnO sputtering targets is between 0.5 and 5 wt% Al2O3 in ZnO however 2wt% is the most common. At lower aluminium concentrations, the electrical conductivity of the film is lower. As the aluminium concentration increases, the electrical conductivity of the film increases. The best balance between conductivity and transparency is found for Al2O3 content of around with 2wt%. If you need a different composition, please let us know.

Typical Materials and Substrates

Al-doped ZnO thin films can be grown on a variety of substrates, including sapphire, gallium arsenide (GaAs), zinc oxide (ZnO), silicon (Si), and gallium nitride (GaN). Polycrystalline Al-doped ZnO thin films can be grown on a wide variety of substrates, including glass, quartz, silicon, and metals.

Typical Properties of Al:ZnO in Thin Film Form

The typical properties of Al:ZnO in thin film form include high electrical conductivity, good optical transparency, and excellent chemical stability. The electrical conductivity of Al:ZnO thin films is typically in the range of 10–15 S/cm, depending on the aluminium concentration in the film. The optical transparency of Al:ZnO thin films can range from 70-90%, depending on the aluminium concentration. Typical

Deposition Conditions for Al:ZnO Thin Films by Sputtering

The typical deposition conditions for Al:ZnO thin films by sputtering include a substrate temperature of between 200-400˚C, a pressure of between 1-2 mTorr, and a DC sputter power of between 0.5-1kW. The thickness of the film can range from 10-100nm, depending on the deposition time.

Typical Deposition Conditions for Al:ZnO Thin Films by Pulsed Laser Deposition

The typical deposition conditions for Al:ZnO thin films by pulsed laser deposition include a substrate temperature of between 200-400˚C, a laser pulse energy of between 1-2J/cm2, and a laser pulse frequency of between 10-20 Hz. The thickness of the film can range from 10-100nm, depending on the deposition time.

Related Thin Film Materials

ZnSnO3 (Zinc Stannate), ZnSnO4 (Zinc Stannite), ZnSnO2 (Zinc Stannic Oxide), TiO2 (Titanium Dioxide), and Al2O3 (Aluminium Oxide).

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.