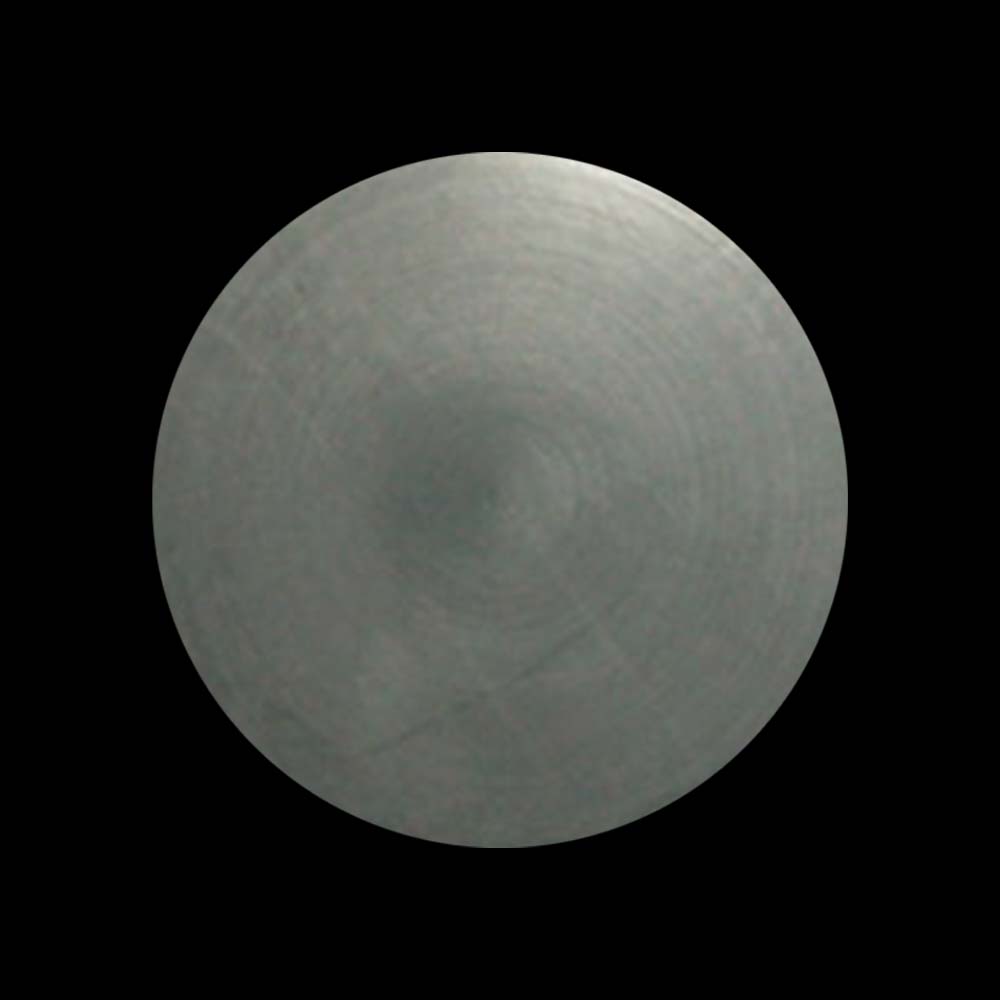

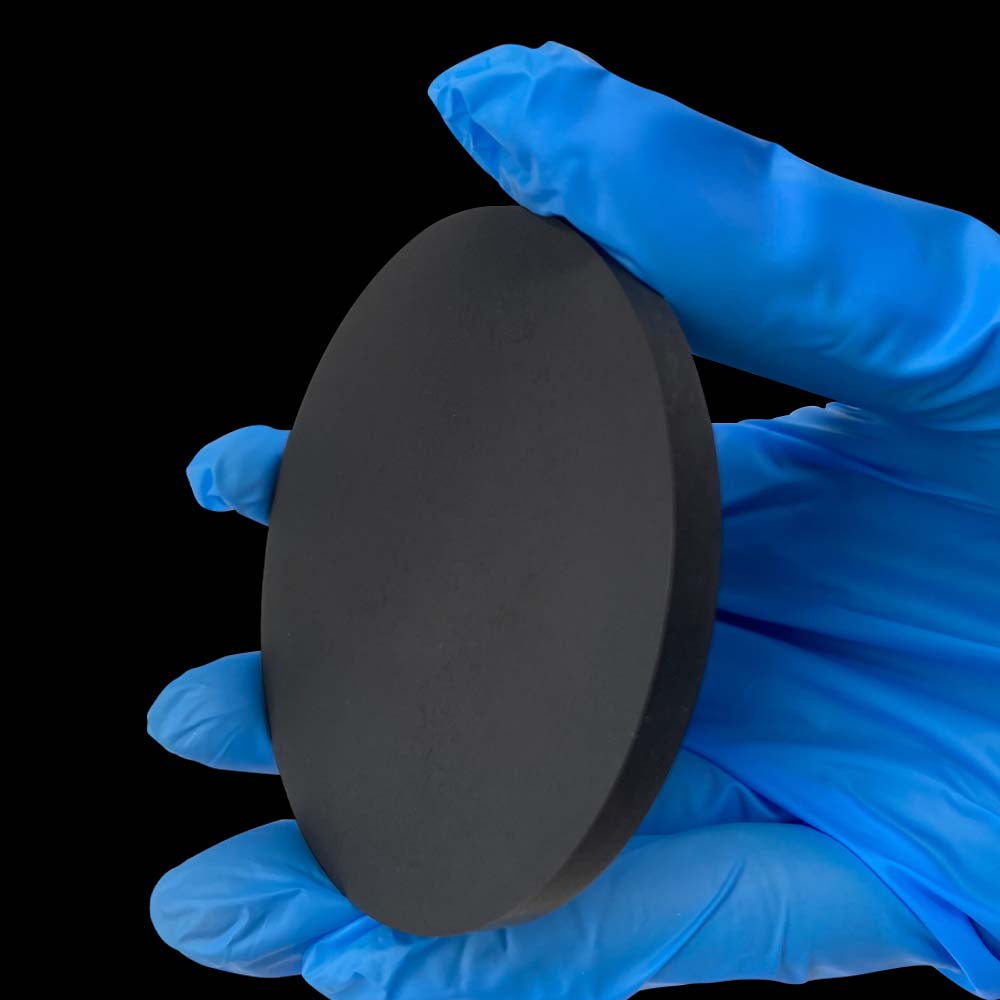

Target Materials

Carbon Sputtering Target

Carbon Sputtering Target

Couldn't load pickup availability

| Material | Carbon |

| Formula | C |

| Purity | 99.99% |

| Typical Substrates | Si, Al2O3 sapphire, Glass |

| Related Materials | TiN, AlN, TiC, WC, SiC |

Introduction to Carbon Thin Films

Carbon thin films offer a variety of research and commercial applications, ranging from energy storage and conversion, to advanced materials for applications such as electronics, optoelectronics, sensors, and biocompatible implants. Carbon thin films are also used in data storage devices and in various optical devices. Carbon thin films have unique optical, electrical, and mechanical properties, making them ideal for a variety of applications. Carbon thin films are typically deposited by vacuum deposition processes such as sputtering, evaporation, and pulsed laser deposition. Carbon can be sputtered with high surface area, good adhesion, low stress, and good electrical conductivity.

What is the Typical Conductivity of Carbon thin films

Thin Films The typical conductivity of carbon thin films is dependent on the type of deposition process used. Sputtering is typically used to produce C thin films with good electrical conductivity, while evaporation and pulsed laser deposition are used to produce C thin films with lower electrical conductivity. The electrical conductivity of C thin films is typically in the range of 10-100 S/cm, depending on the deposition process and the type of substrate used.

Common Deposition Conditions for C Films by DC Sputtering

DC sputtering is a popular deposition process for C thin films, due to its low cost and high deposition rates. The typical deposition conditions for C films by DC sputtering include a power of 1-2 kW, a pressure of 0.1-1 mbar, a substrate bias of 0-400V, a distance target-sample of 10-20 cm, and a substrate temperature of 20-400°C.

Common Deposition Conditions for C Films by RF Sputtering

RF sputtering is another popular deposition process for C thin films, due to its high deposition rates and ability to produce films with high electrical conductivity. The typical deposition conditions for C films by RF sputtering include a power of 200-1000 W, a pressure of 0.1-0.5 mbar, a substrate bias of 0-400V, a distance target-sample of 10-20 cm, and a substrate temperature of 20-400°C.

Carbon films can be deposited by pulsed laser deposition. The typical deposition conditions for C films by pulsed laser deposition use a background gas pressure of 10-100 mbar, and a substrate temperature of 20-500°C.

What Substrates Permit Epitaxial Films of C

C can be produced on a variety of substrates, including silicon, diamond, and sapphire. Silicon is the most commonly used substrate, and due to its high purity and low cost it is the preferred choice for epitaxial growth of carbon thin films. Diamond is another substrate for epitaxial growth of C, due to its high thermal conductivity and hardness. Sapphire is also used as a substrate for epitaxial growth of C, due to its low thermal expansion, high thermal conductivity, and low cost.

What Substrates Permit Quality Polycrystalline Films of C

Polycrystalline films of C can be produced on a variety of substrates, including glass, silicon, and sapphire. Glass is the most commonly used substrate, due to its low cost and ease of use. Silicon is also used as a substrate for polycrystalline growth of C, due to its high purity and low cost. Sapphire is also used as a substrate for polycrystalline growth of C, due to its low thermal expansion, high thermal conductivity, and low cost.

Other Techniques to Deposit Carbon

Thin Films Other techniques that can be used to deposit C thin films include evaporation, chemical vapor deposition (CVD), and ion beam deposition. Evaporation is typically used to produce C thin films with good optical properties, while CVD is used to produce C thin films with high surface area and good adhesion. Ion beam deposition is used to produce C thin films with low stress and good electrical conductivity.

5 Other Thin Film Materials Related to C

Titanium nitride (TiN), aluminum nitride (AlN), titanium carbide (TiC), tungsten carbide (WC), and silicon carbide (SiC). These materials are used in a variety of applications, including electronics, optoelectronics, sensors, and biocompatible implants.

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.