Target Materials

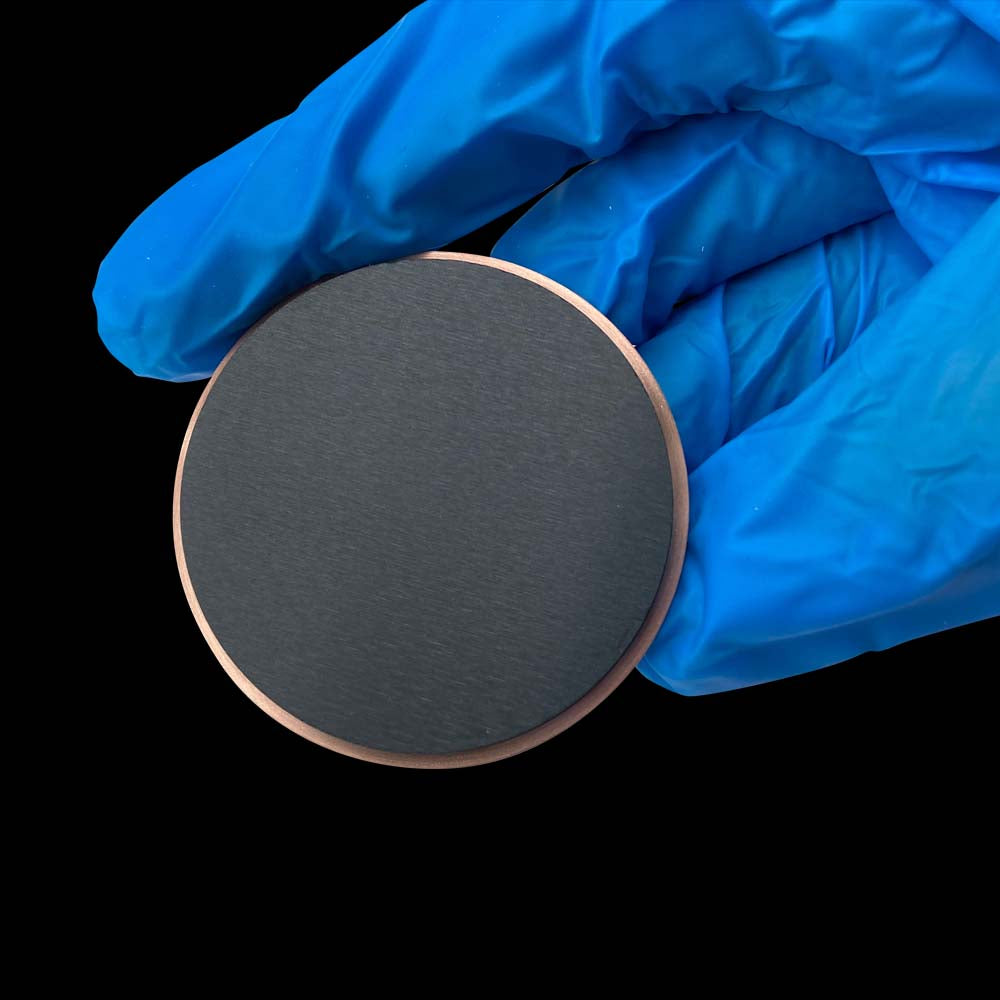

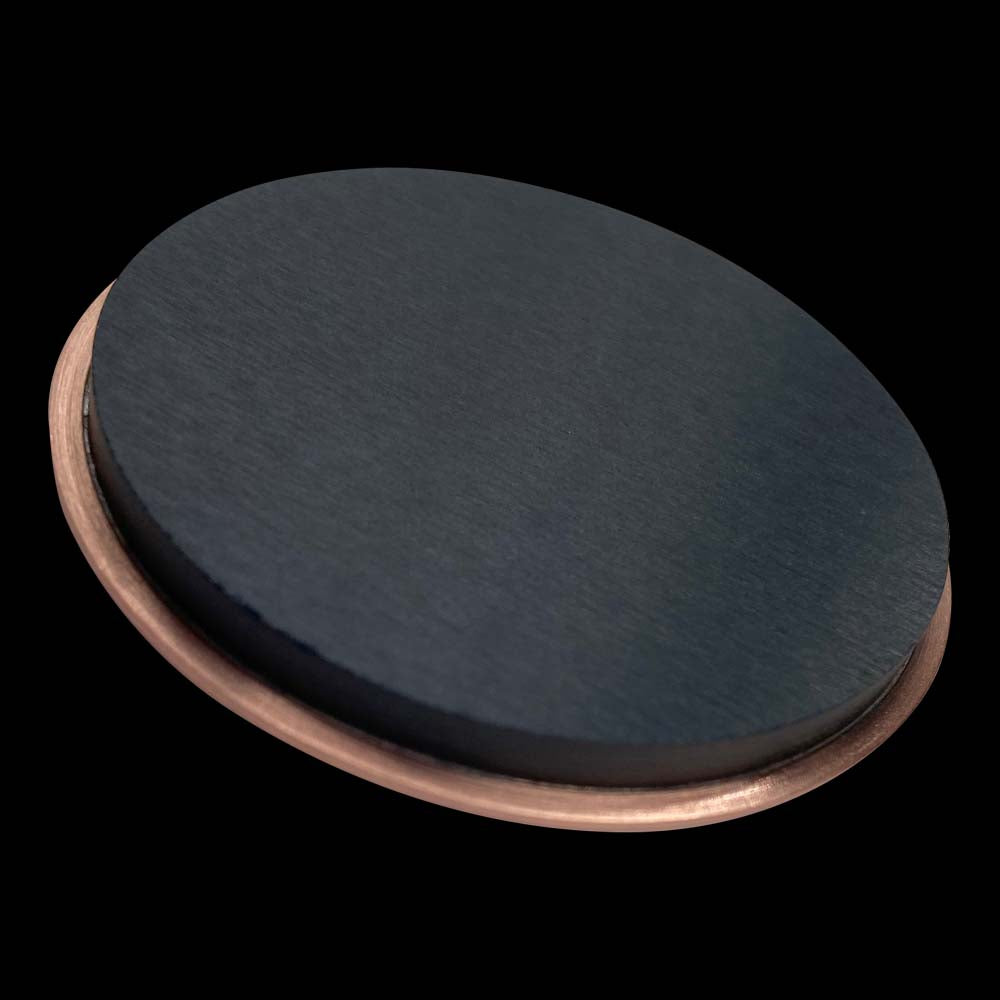

Indium Tin Oxide (ITO) Sputtering Target

Indium Tin Oxide (ITO) Sputtering Target

Couldn't load pickup availability

| Material | Indium Tin Oxide, ITO |

| Formula | 90% In2O3 / 10% SnO2 |

| Purity | 99.99% |

| Typical Substrates | Glass, PET |

| Related Materials | Ga:ZnO Al:ZnO CdSnO3 NiSnO3 CIGS MoSnO3 TiO2 SnO2 |

Indium tin oxide (ITO) is the most common transparent conductive oxide used with high conductivity and optical transparency and it can be deposited at relatively low temperatures meaning is can be applied to various different substrates, the most common of which being glass.

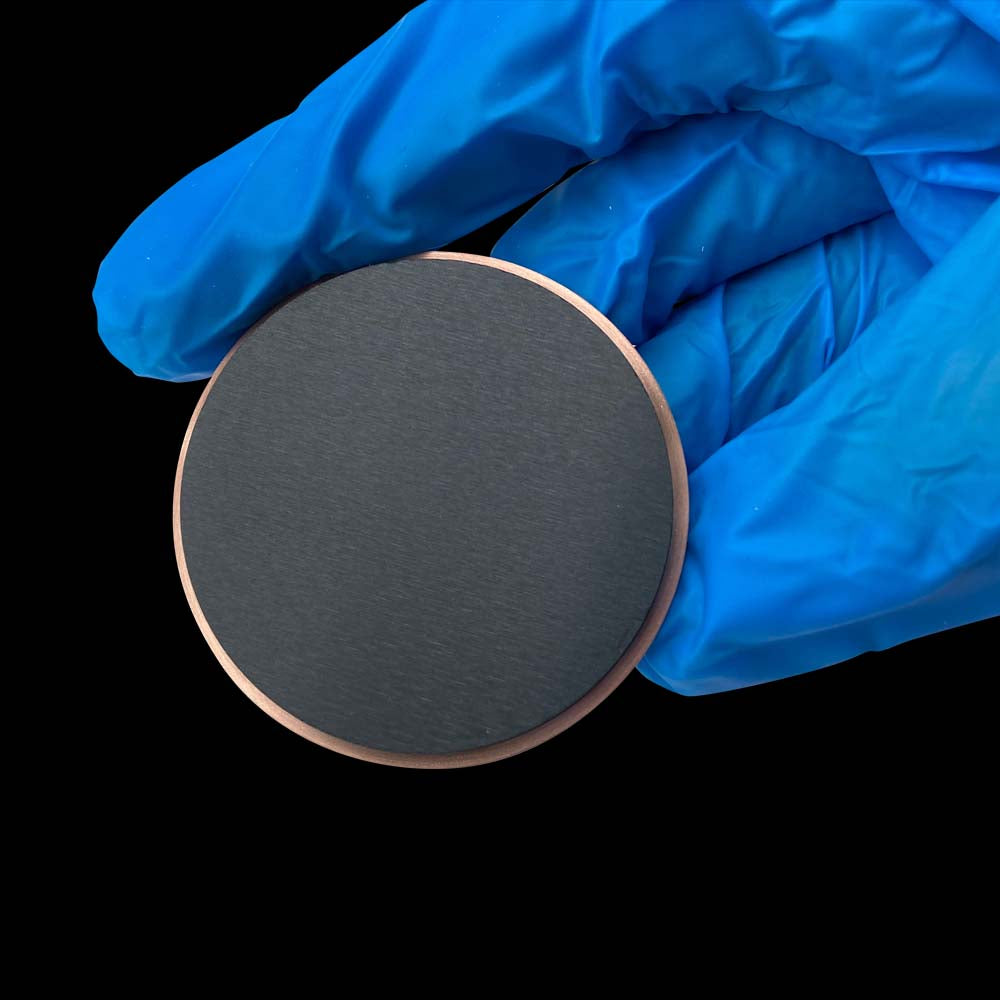

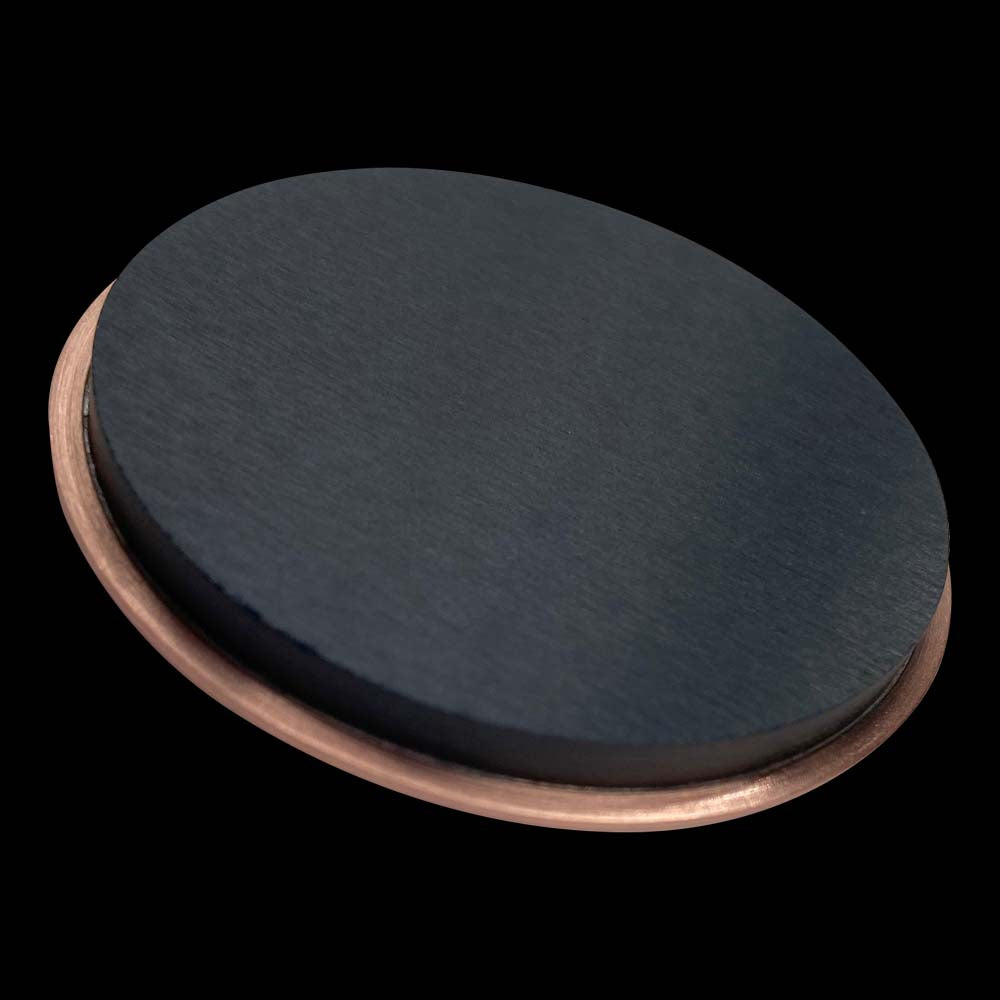

ITO targets are typically composed of a mix of In2O3 and SnO2, with 90:10 ratio being the most common as it has a good compromise of transparency and conductivity. ITO targets are light yellow to pale green color in target form but transparent in thin film form.

The Common Uses of ITO Thin Films

In commercial product applications, ITO is commonly used in touch screens, displays, solar cells, and antireflection coatings. ITO thin films are highly transparent and can be used to reduce reflections from reflective surfaces, such as displays. Additionally, the thin film’s electrical conductivity makes it ideal for use in touch screens, as it can be used to detect the location of a user’s finger or stylus on the surface. ITO thin films are also used to make transparent conducting electrodes for LEDs and solar cells, as they are able to efficiently capture and transfer current without interfering with the light entering the cell.

Typical Properties of ITO in Thin Film Form

ITO thin films generally have a high transparency, with a visible light transmission of around 80-90%. The sheet resistance of ITO thin films is typically between 10-20 ohms/square for 140-180 nm, and this value decreases as the film thickness increases and vice versa. Additionally, the optical and electrical properties of ITO thin films can be tailored by varying the composition of the sputtering target. For example, an In-SnO2 target will generally produce a thin film with higher transparency and lower sheet resistance compared to an In2O3-SnO2 target.

Typical Deposition Conditions for ITO Thin Films by Sputtering

ITO thin films can be deposited by sputtering using a range of deposition parameters. Generally, the sputtering pressure is set between 0.1-1 mTorr, and the sputtering power is set between 0.5-2 kW. The deposition temperature is typically kept between room temperature and 300°C, and the deposition rate is typically around 0.5-2 nm/s.

Typical Deposition Conditions for ITO Thin Films by Pulsed Laser Deposition

ITO thin films can also be deposited by pulsed laser deposition (PLD). The deposition parameters for PLD with an oxygen pressure of 5-50 mTorr if films are oxygen deficient then they can appear grey. ITO can be deposited from room temperature to 400C which means it can be deposited on plastics as well as glass and other substrates. Laser energy density is typically 0.75-1.5 J.cm-2

Related products:

Al: ZnO

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.