Target Materials

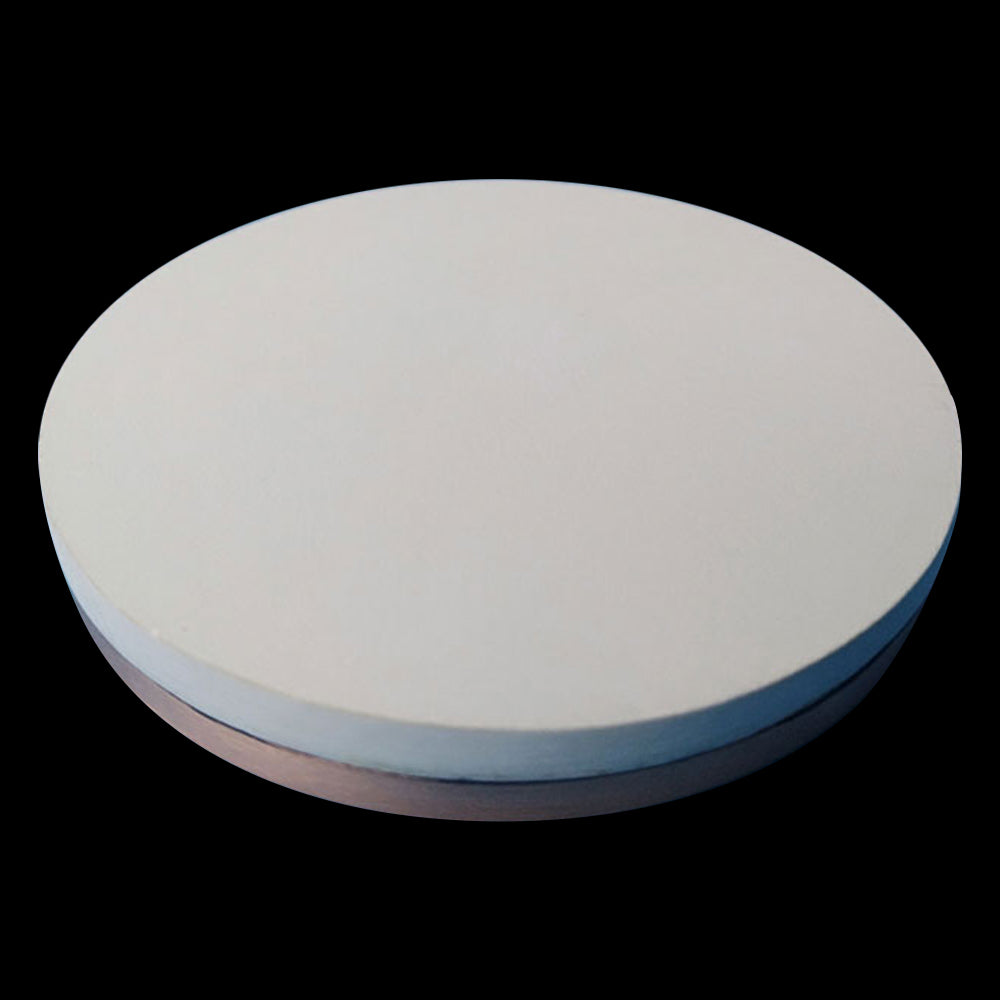

Lithium Titanate Li4Ti5O12 PLD Target

Lithium Titanate Li4Ti5O12 PLD Target

Couldn't load pickup availability

| Material | Lithium Titanate |

| Formula | Li4Ti5O12 |

| Purity | 99.9% |

| Typical Substrates | SrTiO3, LaAlO3, MgAl2O4 |

| Crystal Structure | Spinel |

Introduction to Lithium Titanate Thin Film

Lithium Titanate (Li4Ti5O12) is a promising anode material for lithium-ion batteries due to its high stability, excellent rate capability, and long cycle life. In thin film form, it offers several advantages over bulk material, such as higher surface area, better electronic conductivity, and improved structural stability.

Lithium Titanate (Li4Ti5O12) thin film is a promising material used in energy storage, such as lithium-ion batteries, and has attracted attention for its high ionic conductivity and stability. It also has excellent mechanical stability and a unique crystal structure, which makes it suitable for various thin film applications.

There are several methods to deposit lithium titanate thin films, including pulse laser depsoition (PLD) chemical vapor deposition (CVD), sputtering, and sol-gel. CVD is a popular method for depositing high-quality lithium titanate thin films, but it requires high temperatures and vacuum conditions.

Ionic Conductivity and Stability of Lithium Titanate

Lithium Titanate has high ionic conductivity, which means that it can efficiently transport lithium ions between its lattice sites. This property is beneficial for its use in energy storage devices, where fast charging and discharging rates are desired. Additionally, lithium titanate is stable, even at high temperatures, making it a reliable material for long-term use.

Mechanical Stability of Lithium Titanate

Lithium Titanate has superior mechanical stability, thanks to its high hardness and elastic modulus. This property is essential for the durability of thin film devices, which require robust materials to withstand the stresses of use.

Advantages of Lithium Titanate

- High ionic conductivity

- Stability at high temperatures

- Excellent mechanical stability

- Reliable for long-term use

- Suitable for various thin film applications

Crystal Structure of Lithium Titanate

Lithium Titanate has a spinel crystal structure, with lithium ions occupying the tetrahedral sites and titanium ions occupying the octahedral sites. This unique structure allows for efficient ion transport and makes it suitable for use in energy storage devices.

Typical Substrates for Epitaxial Growth of Lithium Titanate

Typical substrates with a good lattice match for the epitaxial growth of Lithium Titanate include:

- MgAl2O4

- Al2O3

- SrTiO3

- LaAlO3

- Sapphire

Other Similar Thin Film Materials to Lithium Titanate

Other similar thin film materials to Lithium Titanate include:

- Lithium Niobate (LiNbO3)

- Lithium Tantalate (LiTaO3)

- Lithium Cobalt Oxide (LiCoO2)

- Lithium Iron Phosphate (LiFePO4)

- Lithium Manganese Oxide (LiMn2O4)

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.