Target Materials

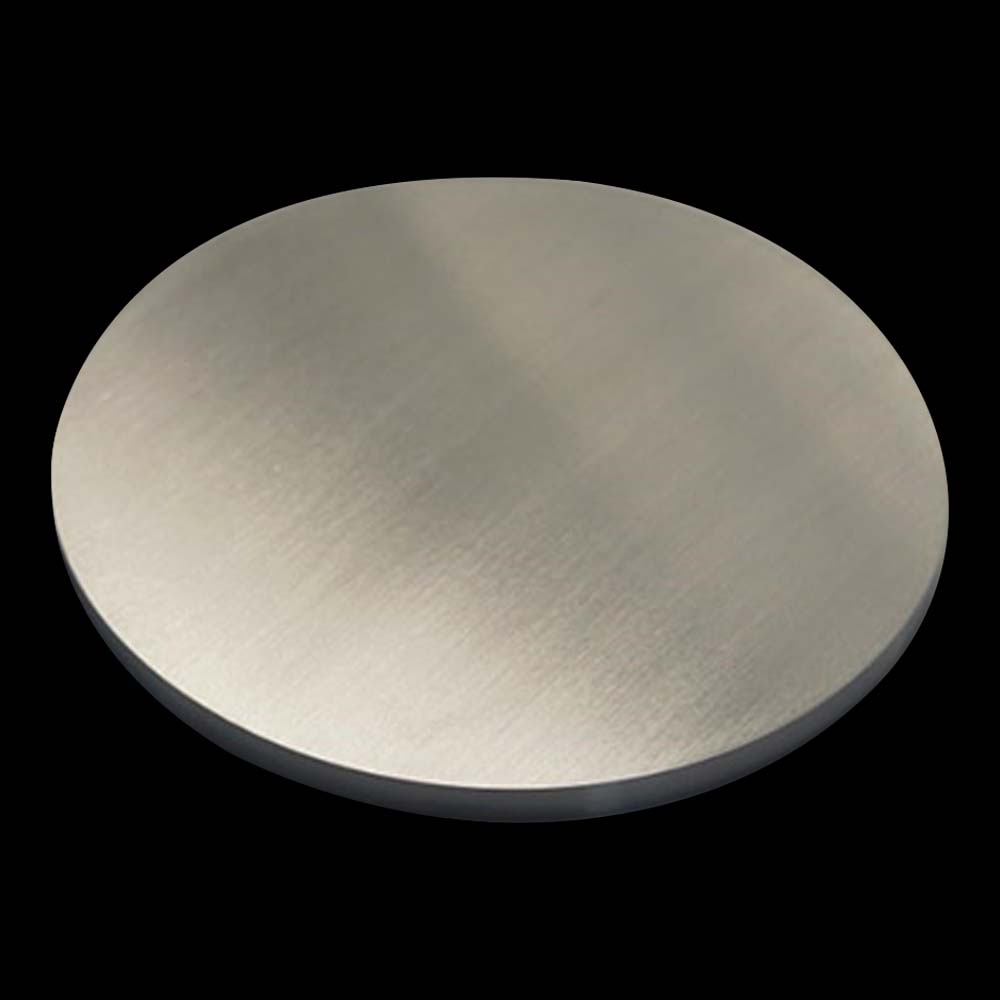

Molybdenum (Mo) Sputtering Target

Molybdenum (Mo) Sputtering Target

Couldn't load pickup availability

| Material | Molybdenum |

| Formula | Mo |

| Purity | 99.99% |

| Typical Substrates | Al2O3 (sapphire), Si, glass, quartz (SiO2) |

| Related Materials | Cr, Ti, W, Ta, Nb |

Molybdenum (Mo) thin films are widely used in research and commercial applications due to their high thermal and electrical conductivity. The use of molybdenum thin films is often preferred over other materials due to its superior properties, including high melting point, low vapor pressure, and excellent oxidation resistance. Mo thin films are commonly used in electronics and optoelectronics applications, such as in thin film transistors and solar cells. Mo thin films are also used in optical and structural components, including mirrors, optical coatings, and thin film sensors. In addition, Mo thin films are used in medical devices, such as pacemakers, and in industrial applications, such as for coating machine tools to enhance wear resistance.

How are Molybdenum Thin Films Usually Deposited?

The most common method for depositing Mo thin films is by sputtering. In sputtering, the Mo target is bombarded with energetic particles, usually ions, in order to eject Mo which condenses on a substrate to form a thin film. Other deposition techniques for Mo thin films include electron beam evaporation, chemical vapor deposition, and pulsed laser deposition.

What Substrates Support Epitaxial Growth of Molybdenum Thin Films

Epitaxial growth of Mo thin films is possible on certain substrates, such as sapphire and silicon. These substrates are often used in optoelectronic devices, such as solar cells, due to their ability to support the growth of high quality Mo thin films.

What Substrates Support Growth of Quality Polycrystalline Mo Thin Films

Polycrystalline Mo thin films can be deposited on a wide variety of substrates, including glass, quartz, silicon, and sapphire.

Other Materials Related to Mo

Chromium (Cr), titanium (Ti), tungsten (W), tantalum (Ta), and niobium (Nb). These materials are often used in combination with Mo for thin film applications due to their similar properties, such as high melting points and good oxidation resistance.

Research Papers on the Deposition of Quality Mo Thin Films

1. M. J. G. Vreeswijk et al., "Deposition of high-quality Mo thin films by magnetron sputtering," Applied Surface Science, vol. 253, no. 14, pp. 6338–6342, 2007.

2. K. Y. Choi et al., "Deposition of molybdenum thin films using pulsed laser deposition," Thin Solid Films, vol. 517, nos. 7–8, pp. 2310–2315, 2009.

3. C. Y. Kim et al., "Deposition of molybdenum thin films on quartz substrates by pulsed laser deposition," Applied Surface Science, vol. 256, no. 10, pp. 2915–2920, 2010.

4. Y. H. Kim et al., "Deposition of high-quality molybdenum thin films by magnetron sputtering," Thin Solid Films, vol. 567, pp. 328–331, 2014.

5. V. P. Schulz et al., "Deposition of molybdenum thin films by pulsed laser deposition on Si(111) substrates," Thin Solid Films, vol. 602, pp. 49–53, 2015.

Interesting Facts About Molybdenum

1. Molybdenum was first discovered in 1778 by Carl Wilhelm Scheele, a Swedish chemist.

2. Molybdenum has the sixth highest melting point of any element, at 2,623°C.

3. Molybdenum has the highest boiling point of any element that does not form a solid at room temperature, at 4,630°C.

4. Molybdenum is used in steel alloys to increase hardness and strength, as well as in electrical and electronic components due to its high electrical and thermal conductivity.

5. Molybdenum is also used in catalysts and in the production of fertilizers, dyes, and lubricants.

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.