Target Materials

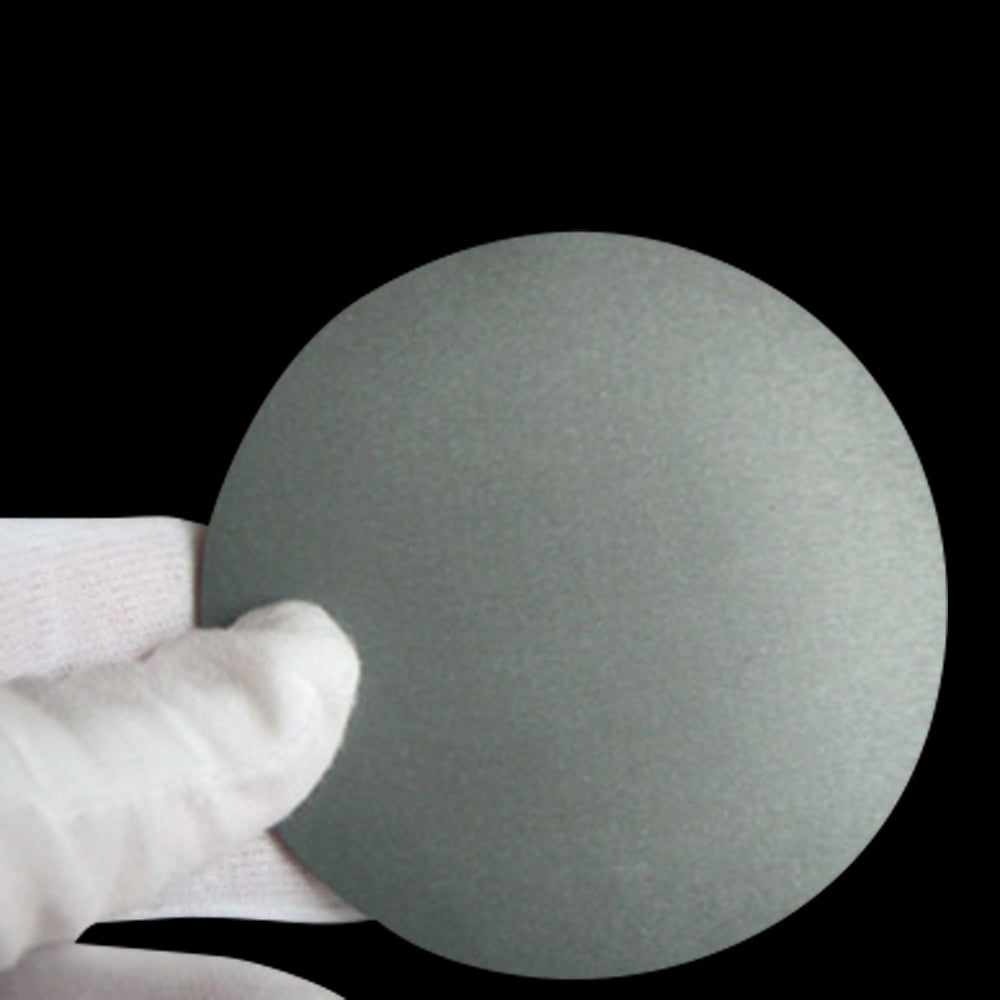

LMNO Spinel (LiNi0.5Mn1.5O4) PLD Target

LMNO Spinel (LiNi0.5Mn1.5O4) PLD Target

Couldn't load pickup availability

| Material | Ni-Mn or LMNO Spinel Cathode |

| Formula | LiNi0.5Mn1.5O4 |

| Common Substrates | SrTiO3,MgO |

| Similar Materials | Lithium Cobalt Oxide, Lithium Iron Phosphate, Lithium titanium oxide |

| Crystal Structure | Spinel |

Introduction to Li-Ni-Mn-Spinel Thin Film

The name of the material is LiNi0.5Mn1.5O4, which is a type of lithium-ion battery cathode material. It is commonly known as Ni-Mn-Spinel or also called LMNO is a mixed metal oxide thin film with a spinel crystal structure that has gained a lot of attention due to its potential applications in energy storage and conversion devices. The abbreviation LMNO stands for Lithium Manganese Nickel Oxide.

LMNO thin film cathodes have demonstrated good electrochemical properties such as high capacity, long cycle life, and high rate capability. It has been extensively studied as a cathode material for rechargeable lithium-ion batteries. This material is known for its high operating voltage and good cycling stability, making it a promising candidate for use in high-energy-density lithium-ion batteries.

Thin film is being deposited on SrTiO3 substrates and for electrochemical testing, they can be deposited on SrRuO3 high conducting lattice matched interlayers. Sometimes, Nb-doped SrTiO3 substrates are also used but typically not as easy for electrochemical measurements as SrRuO3 interlayers.

Application of LMNO Spinel Cathode

LMNO Spinel Cathode is used as a cathode material in rechargeable lithium-ion batteries. It has been shown to exhibit high specific capacity, good cycling stability, and excellent rate performance, making it a promising candidate for next-generation high-energy-density batteries.

Advantages of LMNO Spinel Cathode

- High specific capacity

- Good cycling stability

- Excellent rate performance

- Low cost

- Abundant resources

Comparison to Similar Materials

Compared to other similar materials, LMNO Spinel Cathode exhibits better electrochemical performance and lower cost. For example, LiCoO2 has a higher specific capacity but is more expensive and less stable than LMNO Spinel Cathode.

Crystal Structure of LMNO Spinel Cathode

LMNO (LiNi0.5Mn1.5O4) belongs to the spinel crystal structure, which is a type of cubic close-packed (ccp) crystal structure. The spinel structure consists of two interpenetrating face-centered cubic (fcc) lattices, where one lattice contains cations (metal ions) and the other lattice contains anions (oxygen ions).

The crystal structure is composed of cubic close-packed oxygen atoms, with metal ions occupying some of the octahedral and tetrahedral sites within the structure. The lattice constant of LMNO is typically in the range of 8.1-8.4 Å. The crystal structure of LMNO can be represented by the general formula AB2O4, where A is a divalent metal cation (in this case, Ni) and B is a trivalent metal cation (in this case, Mn).

Typical Substrates for Epitaxial Growth of LMNO Spinel Cathode

Typical substrates with a good lattice match for the epitaxial growth of LMNO Spinel Cathode include MgO, Al2O3, and SrTiO3.

List of 5 Other Similar Thin Film Materials to LMNO Spinel Cathode

- Lithium cobalt oxide (LiCoO2)

- Lithium iron phosphate (LiFePO4)

- Lithium nickel cobalt aluminum oxide (LiNiCoAlO2)

- Lithium manganese oxide (LiMn2O4)

- Lithium titanium oxide (Li4Ti5O12

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.