Target Materials

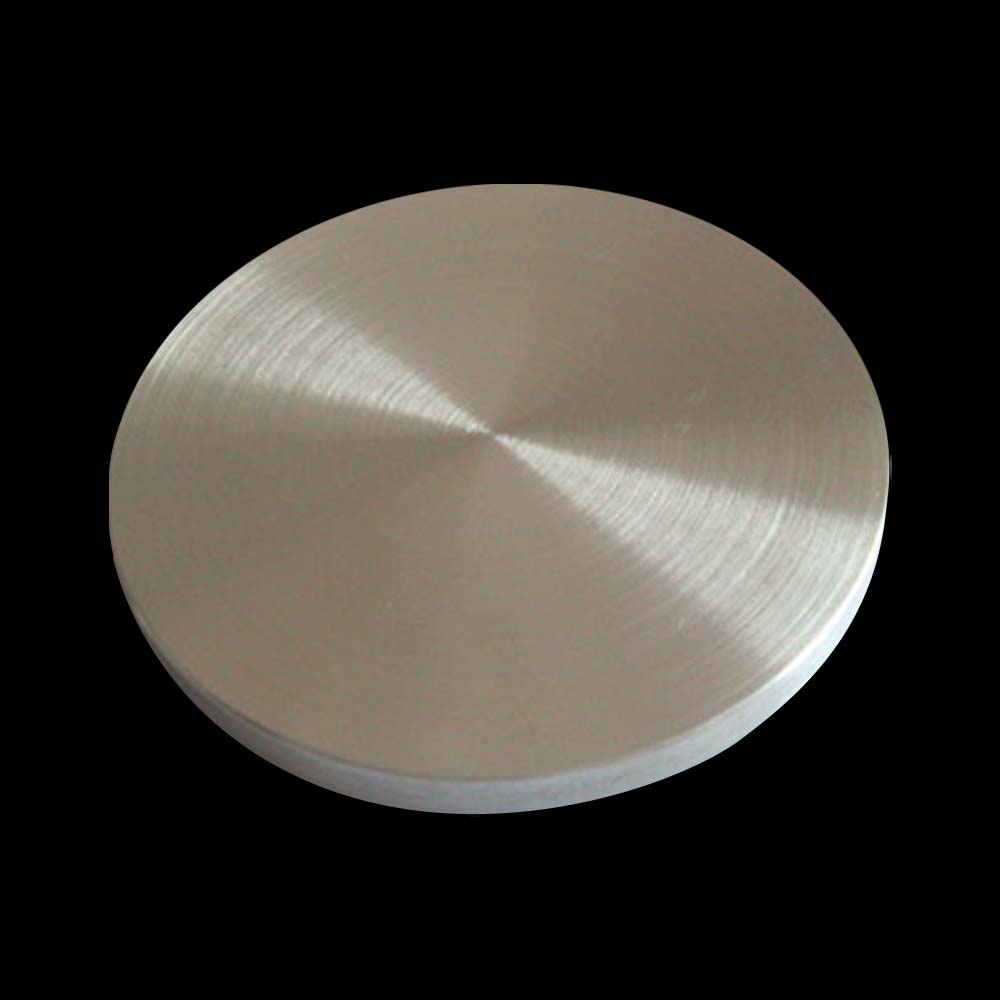

Nickel (Ni) Sputtering Target

Nickel (Ni) Sputtering Target

Couldn't load pickup availability

| Material | Nickel |

| Formula | Ni |

| Purity | 99.99% |

| Typical Substrates | Cu, Al, GaAs, Si, Ti, glass |

| Related Materials | Ti, Cr, Co, Cu, Mo |

Nickel thin films are widely used in research and commercial applications, such as electronics and energy storage. They are used in a variety of devices, such as solar cells, transistors, and batteries. Nickel thin films are also used in magneto-optic storage media, sensors, and catalytic converters. Furthermore, they are used in semiconductor devices such as thin-film transistors, thin-film integrated circuits, and thin-film diode laser arrays. Nickel thin films are highly corrosion-resistant and have very high electrical and thermal conductivities. They are also very strong and have excellent adhesion properties. This makes them ideal for use in electronic devices and other applications requiring strong, corrosion-resistant thin films. Nickel thin films can also be deposited on a variety of substrates and are often used in combination with other thin films, such as aluminum and titanium, to create multi-layer thin-film devices.

Nickel thin films also have a much higher melting point than these other metals, which makes them well-suited for use in high-temperature applications. Furthermore, nickel thin films have a low coefficient of friction, making them suitable for use in lubricants.

How are Nickel Thin Films Usually Deposited

Nickel thin films are usually deposited by physical vapor deposition (PVD), such as sputtering or evaporation. In these techniques, a target material is placed in a vacuum chamber and is bombarded with energetic ions, particles, or photons, which cause the material to vaporize and form a thin film on the substrate.

What Substrates Support Epitaxial Growth of Nickel Thin Films?

Nickel thin films can be grown epitaxially on a variety of substrates, such as copper, aluminum, gallium arsenide, silicon, and titanium.

What Substrates Support Growth of Quality Polycrystalline Ni Thin Films?

The deposition of quality polycrystalline Ni thin films is typically done by physical vapor deposition or chemical vapor deposition techniques. Polycrystalline Ni thin films can be grown on a variety of substrates, such as glass, plastic, and metal.

Research Papers on Deposition of Quality Nickel Thin Films

1. "Electrical and structural properties of Ni thin films grown by pulsed laser deposition" by M.I. Ahmad and S. Abdel-Aal, published in Applied Surface Science, Volume 291, 2014

2. "Electrochemical sputtered Ni thin films for tribological applications" by F. Jäger, N. Fiebig, and R. Hölzer, published in Thin Solid Films, Volume 517, 2009

3. "Characterization and properties of Ni thin films deposited by magnetron sputtering" by D.S. Kim and Y.H. Kim, published in Applied Surface Science, Volume 252, 2006

4. "Growth and characterization of Ni thin films by radio-frequency magnetron sputtering" by G.T. Kim, S.H. Yun, and S.W. Kim, published in Thin Solid Films, Volume 441, 2003

5. "Fabrication of Ni thin films by magnetron sputtering" by S.H. Hwang and G.B. Choi, published in Thin Solid Films, Volume 287, 1996

Interesting Facts About Nickel

1. Nickel was first used by ancient civilizations for decorative purposes, such as coins and jewelry.

2. Nickel was first isolated from its ore in 1751 by Swedish chemist Axel Cronstedt.

3. Nickel alloys, such as Monel and Inconel, are used in applications that require high strength and corrosion resistance.

4. Nickel is an important component of rechargeable batteries, such as those used in electric vehicles.

5. Nickel-based superalloys are used in applications requiring high temperature and corrosion resistance, such as jet engines.

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.