Target Materials

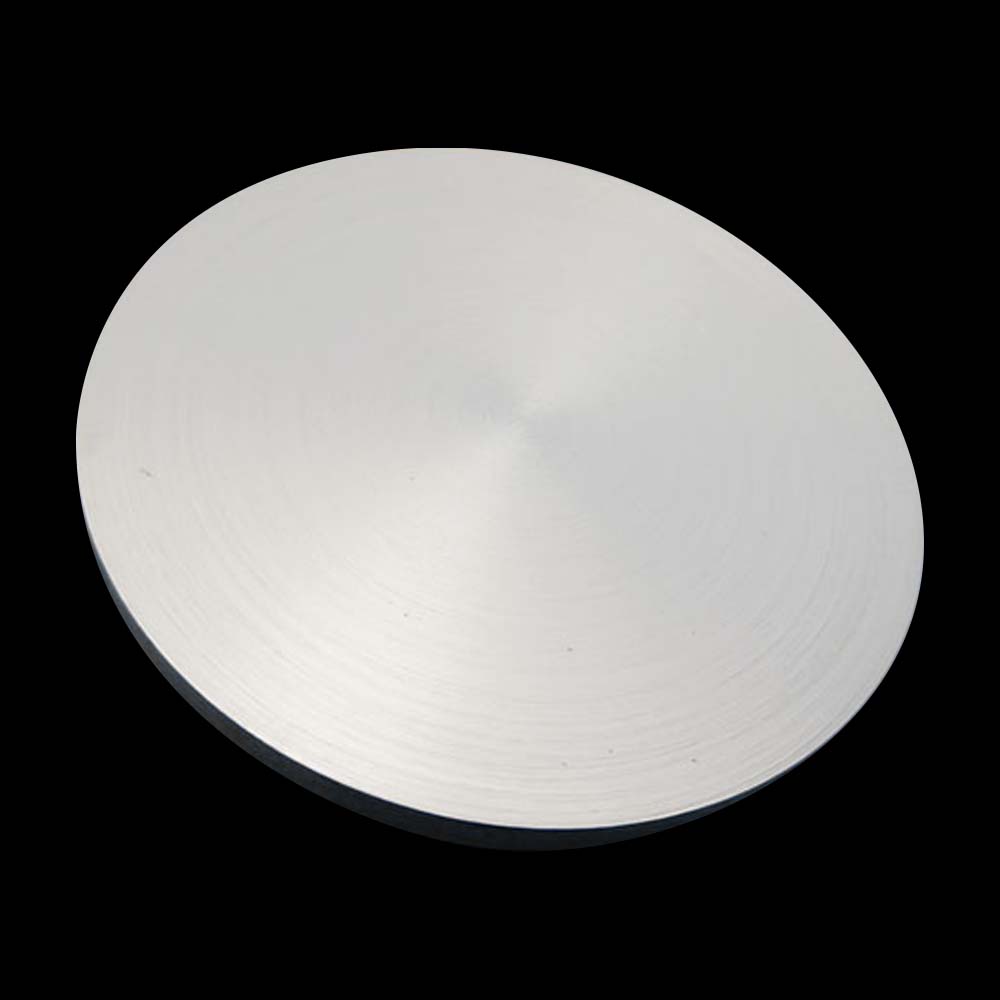

Silver (Ag) Sputtering Target

Silver (Ag) Sputtering Target

Regular price

$200.00 USD

Regular price

Sale price

$200.00 USD

Unit price

per

Shipping calculated at checkout.

Couldn't load pickup availability

| Material | Silver |

| Formula | Ag |

| Purity | 99.995% |

| Typical Substrates | Glass, Silicon, Metal |

| Related Materials | Au, Cu, Pd, Pt Al |

Silver thin films are one of the most widely used thin film materials. Silver thin films are used in a variety of commercial applications, such as printed electronics, photovoltaics, medical devices, and optical coatings. Silver thin films are used in these applications due to their high electrical conductivity, low resistivity, and excellent optical properties. Silver thin films are typically deposited using sputtering techniques, such as DC sputtering and RF sputtering. Silver thin films can also be deposited using other techniques, such as evaporation, PLD, chemical vapor deposition, and electroplating.

What Devices are Silver Thin Films Used In?

Silver thin films are used in a variety of devices, including printed electronics, photovoltaics, medical devices, and optics. In printed electronics, silver thin films are used as conductive layers in printed circuit boards, flexible displays, and other printed electronics. In photovoltaics, silver thin films are used as conductive layers in solar cells. In medical devices, silver thin films are used as conductive layers in electrodes and implants. In optics, silver thin films are used as reflectors and filters.

What Substrates Support Epitaxial Growth of Ag?

Silver thin films can be grown epitaxially on a variety of substrates, such as silicon, quartz, and glass. Silver thin films can also be grown epitaxially on other metals, such as copper and aluminum. What are the Typical Conductivity of Ag Thin Films?

The conductivity of silver thin films depends on the thickness and purity of the film. Generally, silver thin films have a conductivity of approximately 10^7 S/m. This is much higher than other metals, such as copper and aluminum, which have a conductivity of approximately 10^6 S/m.

DC Sputtering vs RF Sputtering for Ag thin films?

Both DC sputtering and RF sputtering are suitable for Ag growth. DC sputtering is generally used for lower temperature processes, while RF sputtering is used for higher temperature processes. In terms of popularity, DC sputtering is the most commonly used technique for Ag deposition.

Other Techniques which are commonly used to deposit Ag thin films

Apart from sputtering, other techniques can be used to deposit Ag thin films, such as evaporation, Pulsed laser deposition (without oxygen), chemical vapor deposition, and electroplating. Evaporation is used to deposit Ag thin films at relatively low temperatures. Chemical vapor deposition is used to deposit Ag thin films at higher temperatures. Electroplating is used to deposit Ag thin films on to conductive substrates.

Thin Film Materials Related to Ag

Other thin film materials related to Ag include gold, copper, aluminum, titanium, and chromium. Gold thin films are used in printed electronics, photovoltaics, and optics. Copper thin films are used in printed electronics and photovoltaics. Aluminum thin films are used in printed electronics, photovoltaics, and optics. Titanium thin films are used in printed electronics and medical devices. Chromium thin films are used in printed electronics and optics.

Research Papers About Ag Thin Films

1. "Electronic and Structural Properties of Ultrathin Silver Films" by P. M. Koenig et al. (2003).

2. "Morphology and Structure of Silver Thin Films on Silicon Substrates" by S. M. Kuznetsov et al. (2008).

3. "Growth Kinetics and Surface Morphology of Silver Thin Films" by R. F. Knecht et al. (2009).

z4. "Structure and Properties of Silver Thin Films on Silicon Substrates" by C. G. White et al. (2010).

5. "Silver Thin Films for Optoelectronic Applications" by M. S. Chaudhry et al. (2013).

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.