Target Materials

Titanium Dioxide (TiO2) Sputtering Target

Titanium Dioxide (TiO2) Sputtering Target

Couldn't load pickup availability

| Material | Titanium Dioxide, Titania |

| Formula | TiO2 |

| Purity | 99.99% |

| Typical Substrates | Glass, Quartz, Polymers, Silicon and Silicon Dioxide |

| Related Materials | Al2O3, ZrO2, Ta2O5, BaTiO3, HfO2 ZnO |

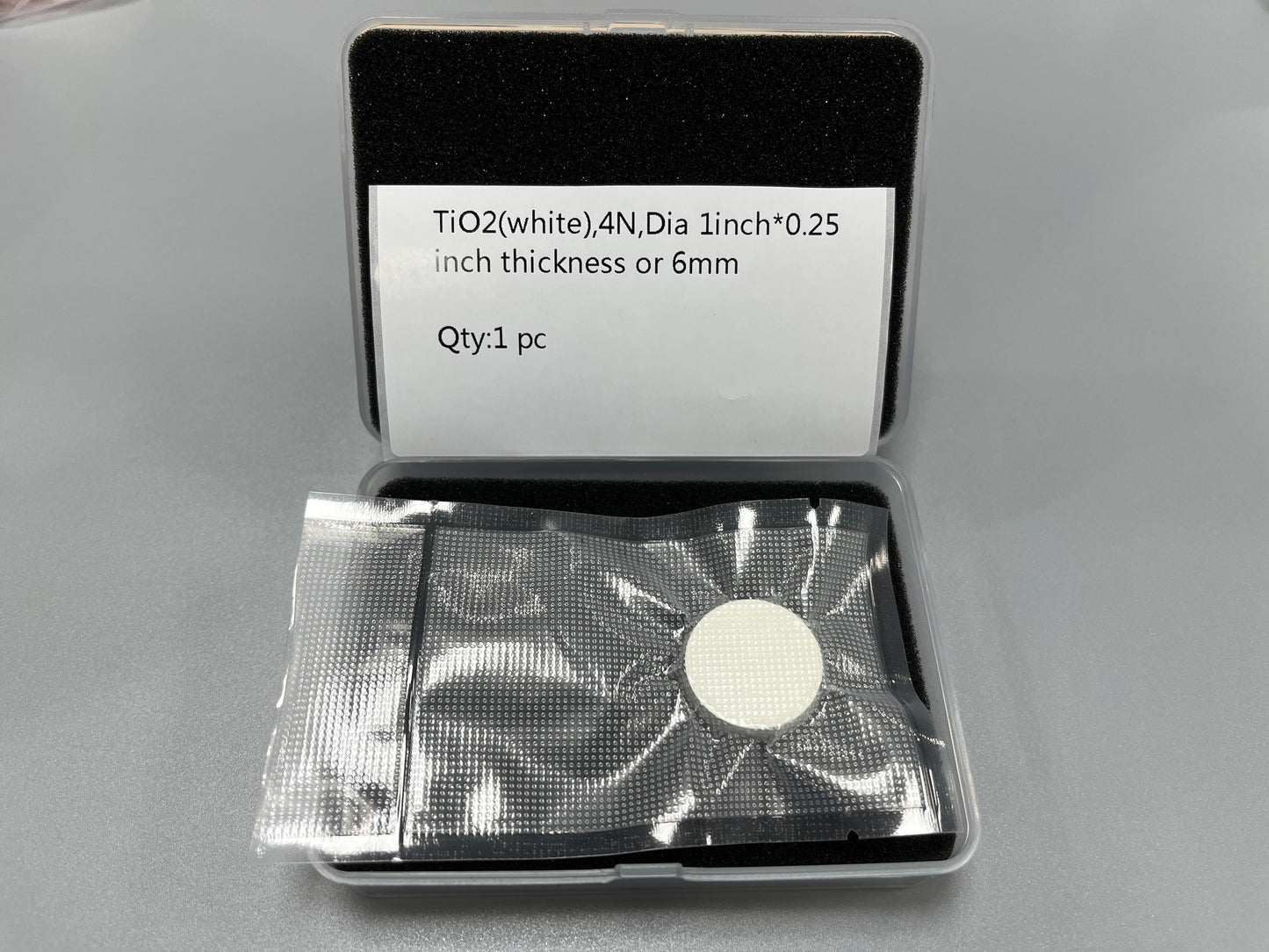

Titanium dioxide (TiO2) is a widely used sputtering target material for thin film deposition. It is a white powder with a wide range of applications in different industries. TiO2 is an inert, non-toxic compound, which makes it an excellent choice for many industrial applications. The sputtering target can be made from pure TiO2 or a combination of TiO2 and other materials. It is also available in different shapes, including disks, rods, plates, and tubes. The target has a bright white to off white appearance.

The Common Uses of Sputtered TiO2 in Thin Film Form

TiO2 is an extremely important material for many thin film applications. It is used in a wide range of industries, including electronics, automotive, medical, and aerospace. In the electronics industry, it is used for semiconductor devices, displays, and sensors. In the automotive industry, it is used for coatings and packaging. In the medical industry, it is used for dental implants, prosthetics, and medical implants.

White TiO2 or Black TiO2

White TiO2 targets are sintered in oxygen and have stoichiometric oxygen. Black TiO2 targets are sintered in air and are oxygen deficient (non-stoichiometric oxygen). Non-stoiciometric TiO2 (or TiOx) is of interest for several applications including optoelectronics. We offer both so just choose the one you need.

Typical Substrates TiO2 is Deposited On

Substrates that permit epitaxial films of TiO2 include sapphire, MgO, SrTiO3 as well as homoepitaxy on TiO2. Quality polycrystalline films are readily deposited on TiO2 include SiO2, ZnO, and glass.

What are the Typical Properties of TiO2 in Thin Film Form

TiO2 thin films have excellent electrical, optical, and thermal properties. They are highly transparent, and have high refractive indices. They are also highly resistive and have good adhesion properties, making them ideal for many thin film applications. In addition, TiO2 thin films have low dielectric constants and low thermal conductivity, making them ideal for applications where insulation and heat dissipation are important.

What are the Typical Deposition Conditions for TiO2 Thin Films by Sputtering

TiO2 thin films can be deposited by sputtering in a controlled environment. The deposition process involves the use of a sputtering target, which is made of TiO2, and a gas, such as argon, which is used to sputter the material off the target. The deposition process can be optimized by controlling the pressure, temperature, power, and gas flow. The deposition process can also be optimized by controlling the target-substrate distance and the angle of incidence of the sputtered material.

What are the Typical Deposition Conditions for TiO2 Thin Films by Pulsed Laser Deposition TiO2 thin films can also be deposited by pulsed laser deposition (PLD). In this process, a focused laser beam is used to bombard the surface of a TiO2 target. This process can be optimized by controlling the laser intensity, pulse duration, and substrate temperature. The laser intensity is typically high enough to ablate a thin layer of the target material. The deposited material is then deposited on the substrate.

Research Papers about TiO2 Thin Films

1. "Pulsed Laser Deposition of Titanium Oxide Thin Films and Its Application as a Transparent Conductive Oxide", by P.G. Kotnala and V.K. Kotnala (2015).

2. "Sputtering deposition of Titanium Oxide thin films for gas sensing applications", by D.J.D. Beech et al. (2017).

3. "Structure and Optical Properties of Titanium Oxide Thin Films Prepared by Different Techniques", by A.K. Konne et al. (2016).

4. "Vacuum Deposition of Titanium Oxide Thin Films by Magnetron Sputtering", by Z. Zhang et al. (2016).

5. "Vacuum Deposition of Titanium Oxide Thin Films by Pulsed Laser Deposition", by R.K. Singh et al. (2017).

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.