Target Materials

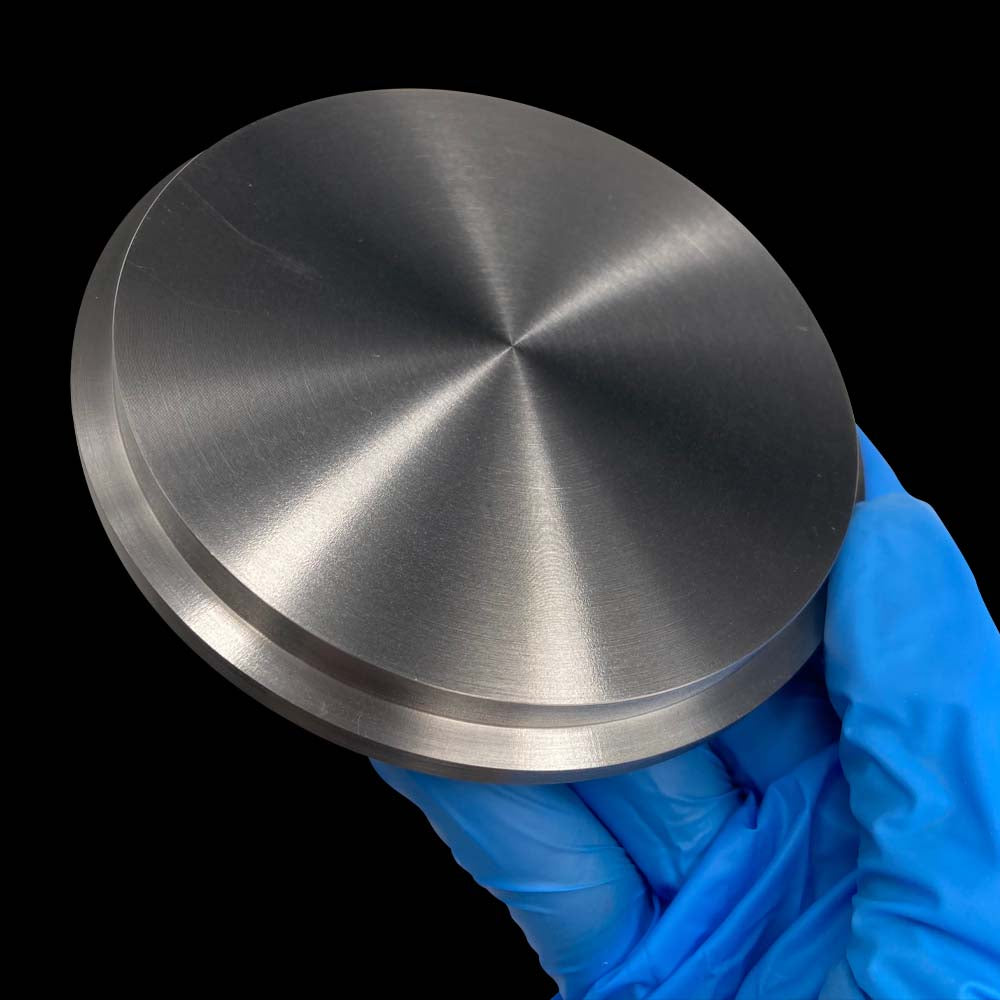

Titanium (Ti) Sputtering Target

Titanium (Ti) Sputtering Target

Couldn't load pickup availability

| Material | Titanium |

| Formula | Ti |

| Purity | 99.99% |

| Typical Substrates | Si, quartz, sapphire (Al2O3), GaAs. Al |

| Related Materials | Ta, Nb, Zr, Hf, Al |

Titanium (Ti) thin films are widely used in both research and commercial applications. In research, these films are used in a variety of fields, such as optoelectronics, nanotechnology, and advanced materials. In commercial applications, Ti thin films are used in a range of devices, including flat-panel displays, medical implants, and microelectronic components. Ti thin films can also be used as protective coatings on a variety of surfaces and as wear-resistant or antifouling coatings. The use of Ti thin films in research is mainly focused on the development of new materials and new technologies. For example, Ti thin films are used in optoelectronic devices such as light-emitting diodes and photovoltaics for improved performance. In materials science, Ti thin films are used to improve the properties of existing materials, such as optical, electrical, and magnetic properties.

Common Deposition Conditions for Titanium Films by DC Sputtering

DC sputtering is the most common method of depositing Ti thin films. The deposition conditions for DC sputtering are typically a power of 1-2 kW, a pressure of 0.1-1 mTorr, a substrate bias of -2-10 V, a distance target-sample of 20-30 cm, and a substrate temperature of 50-80 °C. The deposition rate of Ti films is usually in the range of 1-5 nm/min.

Substrates for Epitaxial Films of Ti

Epitaxial films of Ti can be deposited on various substrates, such as silicon, quartz, sapphire, and gallium arsenide.

Substrates for quality Polycrystalline Films of Ti

Polycrystalline films of Ti can be deposited on a variety of substrates, such as glass, quartz, silicon, and aluminum.

Other Techniques to Deposit Titanium Thin Films

Other techniques to deposit Ti thin films include chemical vapor deposition (CVD), electron beam evaporation, and pulsed laser deposition (PLD).

Research Papers on Titanium Thin Film Deposition

- “Optimization of Titanium (Ti) Thin Films Deposited by DC Magnetron Sputtering”, by A. S. El-Fouly et al. (Thin Solid Films, 2020)

- “Influence of DC Magnetron Sputtering Parameters on the Properties of Titanium Thin Films”, by A. S. El-Fouly et al. (Surface & Coatings Technology, 2019)

- “DC Magnetron Sputter Deposition of Titanium Dioxide Thin Films”, by A. S. El-Fouly et al. (Vacuum, 2018)

- “Vacuum Deposition of High-Quality Titanium Thin Films on Various Substrates by Pulsed Laser Deposition”, by A. Bello et al. (Journal of Vacuum Science and Technology A, 2017)

- “Investigation of Titanium Thin Films Deposited by Pulsed Laser Deposition”, by L. Sun et al. (Journal of Electronic Materials, 2016)

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

-

Free Shipping

Wherever you are, get free shipping on orders from Target Materials

-

High Quality Packaging

All our targets are vacuum packed, sealed and protected so they arrive with you exactly how they left from us.